Definition of Polyester Woven Strapping

Polyester Woven Strapping is a high-strength textile strapping made from high-tenacity woven polyester yarns, designed for securing heavy, uneven, and dynamic loads. Its woven structure delivers high tensile strength, low elongation, excellent tear resistance, and effective shock absorption, allowing the strap to maintain reliable tension during transport and storage.

Features of Polyester Woven Strapping

1. High Tensile Strength

- Made from high-tenacity woven polyester yarns, providing excellent breaking strength for securing heavy and uneven loads.

2. Low Elongation

- Exhibits low stretch under load, helping to maintain stable tension during transport and storage.

3. Excellent Shock Absorption

- Effectively absorbs impacts and vibrations, reducing load movement and damage.

4. Tear Resistant & Non-Splitting

- The woven structure prevents splitting and offers high resistance to tearing, even under dynamic loads.

5. Flexible & Load-Friendly

- Easily conforms to irregular shapes while protecting edges and surfaces from damage

6. Safe Alternative to Steel Strapping

- No sharp edges, no snap-back effect, and non-corrosive, improving operator safety and cargo protection.

7. Re-Tensionable

- Can be re-tensioned if the load settles or volume changes, ensuring continued load security.

8.Wide Compatibility

- Works with wire buckles, manual or pneumatic tensioning tools, and can also be used in bale press machines.Suitable for timber, steel, construction materials, machinery, logistics, and export packaging.hines.

How To Use Plyester Woven Strapping

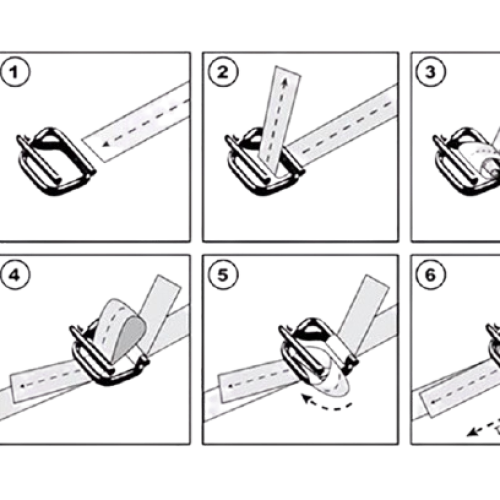

To use polyester woven strapping, first wrap it around your load, then secure one end with a Phosphated buckle by creating a loop and pulling it tight; next, use a tensioner tool (manual or powered) on the loose end to tighten the strap against the buckle, and finally, use a cutter or the tool’s blade to trim the excess for a safe, clean finish, using a dispenser cart for efficiency.

Phosphated Wire Buckles

Polyester Woven Strapping coil

Hand Tensioner

Dispenser Cart

Polyester Woven Strapping tensioned with Phosphated Wire Buckle

Steps for Usage

Polyester Woven Strapping with Phosphated Wire Buckle

Polyester Woven Strapping Application

Polyester Woven Strapping Specifications

| Product Code | Width | Linear strength | System strength | Meters per coil | Coils/box | Coils/pallet |

|---|---|---|---|---|---|---|

| MWS40L | 13mm | 295daN | 450daN | 1200m | 3 | 108 |

| MWS40 | 13mm | 375daN | 550daN | 1100m | 3 | 108 |

| MWS50L | 16mm | 350daN | 550daN | 914m | 3 | 108 |

| MWS50 | 16mm | 450daN | 700daN | 850m | 3 | 108 |

| MWS60 | 19mm | 580daN | 900daN | 600m | 3 | 108 |

| MWS65 | 19mm | 750daN | 1100daN | 500m | 3 | 108 |

| MWS85 | 25mm | 1000daN | 1600daN | 500m | 3 | 108 |

| MWS86 | 25mm | 1200daN | 1900daN | 500m | 2 | 108 |

| MWS92 | 32mm | 1350daN | 2160daN | 100m | 8 | 288 |

| MWS94 | 32mm | 1500daN | 2400daN | 330m | 2 | 108 |

Applications of Polyester Woven Strapping

Polyester woven strapping is widely used for securing heavy, sharp-edged, and high-value loads due to its high tensile strength, flexibility, and excellent shock absorption. Typical applications include:

6. Export Packaging & Container Lashing

- Frequently applied in containerized cargo and overseas shipments as a lightweight alternative to steel strapping.

7.Paper, Pulp & Recycling Industry

- Effective for bundling paper rolls, cartons, waste paper, and recyclable materials.

8.Irregular or Sharp-Edged Loads

- The soft, woven structure prevents damage and improves safety when securing uneven or sharp products.

1.Timber & Lumber Industry

- Ideal for bundling timber, logs, plywood, MDF, and wooden panels, providing strong holding force without damaging the load.

2. Steel & Metal Products

- Commonly used for securing steel coils, pipes, sheets, bars, and aluminum products, especially where surface protection is critical.

3. Building & Construction Materials

- Suitable for bricks, concrete blocks, stone slabs, ceramic tiles, and prefabricated components during transport and storage.

4. Machinery & Heavy Equipment

- Used to secure industrial machinery, engines, compressors, and large equipment for domestic and export shipments.

5. Palletized Goods & Unit Loads

- Ensures stable pallet loads in warehousing and logistics, reducing load shift during handling and transit.

What We Can Do?

We provide a comprehensive range of OEM and ODM services for Polyester Woven Strapping to support your brand’s packaging requirements. Custom colors, printing options, and tailored specifications can be produced to match your exact needs. Whether you require specific widths, strengths, coatings, or branded markings, our team delivers flexible and reliable manufacturing solutions designed for global procurement standards.

FAQs (Frequently Asked Questions) About Polyester Woven Strapping

Polyester woven strapping is a high-strength textile strapping made from woven polyester yarns. It is designed to secure heavy, sharp-edged, or irregular loads during transportation and storage. The woven construction provides excellent flexibility, shock absorption, and load retention.

Polyester woven strapping offers high tensile strength, excellent shock resistance, and consistent tension retention. Unlike steel strapping, it does not rust, has no sharp edges, and is safer for operators and cargo. It is also lightweight and easy to handle.

It is widely used in industries such as timber and lumber, steel and metal products, building materials, machinery, logistics, and cargo securing. It is especially suitable for heavy loads, long-distance transportation, and dynamic loads subject to vibration or impact.

Polyester woven strapping is safer, lighter, and more flexible than steel strapping. It absorbs shocks during transit rather than snapping or loosening, reducing cargo damage. In many applications, it provides comparable system strength at a lower total cost.

Polyester woven strapping is typically available in widths such as 13 mm, 16 mm, 19 mm, and 25 mm. Different grades offer varying linear and system strengths to meet specific load requirements. Custom sizes and strengths may also be available upon request.

Wire buckles, phosphated buckles are commonly used with polyester woven strapping. The choice of buckle depends on strap width, required system strength, and application conditions.

Yes. Polyester woven strapping has excellent resistance to moisture, UV exposure, and temperature variations. It maintains performance in outdoor and harsh environments without corroding or losing strength.

In many cases, polyester woven strapping can be reused if it remains undamaged after unloading. This makes it a cost-effective and environmentally friendly option compared to single-use strapping materials.

It can be tensioned manually using hand tools or with pneumatic tensioners for higher productivity and consistent tension. No heat sealing is required, making installation quick and efficient.

Yes. Polyester woven strapping is recyclable and generates less waste than steel strapping. Its durability and reusability further reduce environmental impact.

Why Us

Quality First

Products tested for tensile strength, elongation, and performance stability.

10 Years of Expertise

Over a decade producing and exporting industrial-grade strapping worldwide.

OEM/ODM Specialists

Custom sizes, strength,printing,labeling, and flexible MOQs to suit your brand’s needs.

System-Based Solutions

We don’t just sell straps — we provide complete load restraint systems.