definition of Polyester Composite Strapping

Polyester Composite Strapping is a high-strength cargo securing material made from polyester fibers encapsulated in a durable polymer coating. Designed with a smooth, rigid structure and superior tensile performance, it offers a safe, non-metallic alternative to steel strapping. Widely used in logistics, timber, metals, and export packaging, it delivers reliable load stability with resistance to moisture, UV, and abrasion.

Features of Polyester Compoiste Strapping

1.High Tensile Strength

- Linear breaking strength from 295 to 1500 daN ensures reliable load security for medium to heavy cargo.

2.High Shock Absorption

- Effectively absorbs tension and impacts during transit, minimizing load shifting and cargo damage.

3.No Damage to Most Surfaces

- Gentle on products, pallets, and packaging materials, preventing scratches or marks.

4. Corrosion-Free & Easy Handling

- Non-metallic construction eliminates rust, simplifies handling, and improves workplace safety.

5.Safe for Shippers and Consignees

- No sharp edges or snap-back hazards during application or removal, reducing workplace injuries.

6. Lightweight and Flexible

- Easy to manipulate around irregular or bulky cargo without additional labor strain.

7. Available Widths 13 mm to 25 mm

- Versatile sizes accommodate various load types and pallet sizes.

8.Cost-Effective Long-Term Solution

- Reduces replacement and maintenance costs compared to steel, improving overall packaging efficiency.

How to use Polyester Composite Strapping

To use polyester composite strapping, you need the strapping material itself, galvanized steel wire buckles, and a tensioner tool—whether manual, battery-powered, or pneumatic. A cutter is essential for trimming excess strap after tensioning, ensuring a clean and safe finish. For efficient handling, a dispenser cart helps organize and dispense the strapping smoothly, preventing tangles and improving workflow during palletizing or bundling operations.

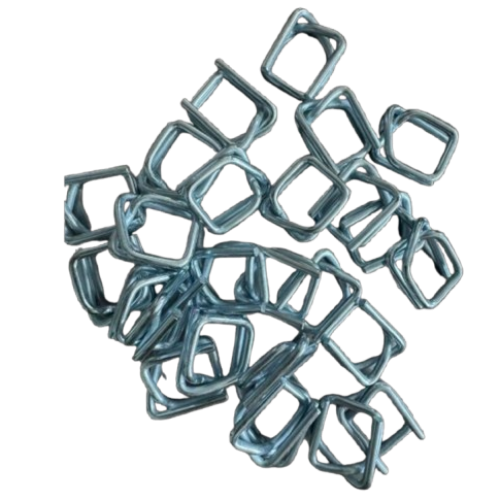

Galvanized Wire Buckles

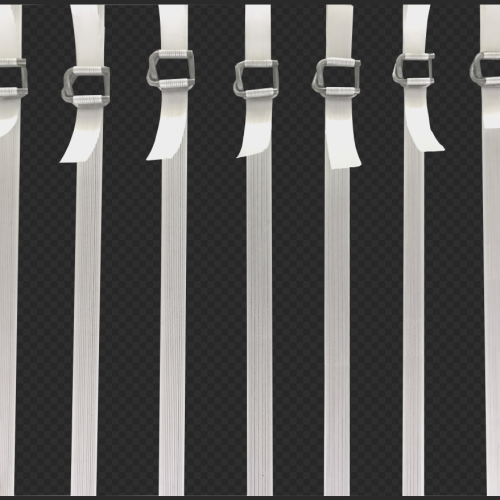

Polyester Composite Strapping

Tensioner tool

Dispenser Cart

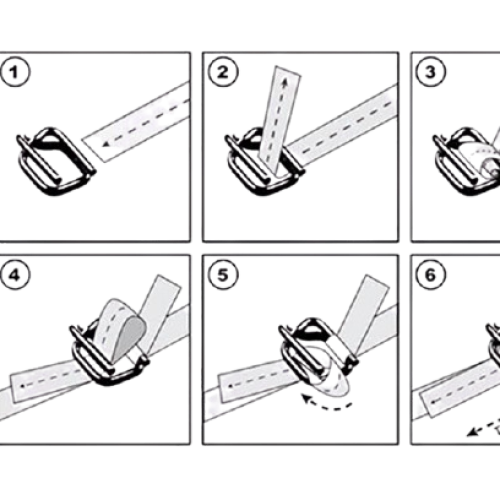

Tensioning the strapping

Steps for how to use

Composite Strapping tensioned with Wire Buckles

Composite Strapping Application

Polyester Composite Strapping Specifications

| Item Name | Width | Linear Strength | System Strength | Meters per Coil | Coils/Box | Coils/Pallet |

|---|---|---|---|---|---|---|

| MC40L | 13 mm | 200 daN | 320 daN | 1100 m | 2 | 60/90 |

| MC40 | 13 mm | 300 daN | 480 daN | 1100 m | 2 | 60/90 |

| MC50L | 16 mm | 285 daN | 460 daN | 850 m | 2 | 60/90 |

| MC50 | 16 mm | 425 daN | 680 daN | 850 m | 2 | 60/90 |

| MC60 | 19 mm | 475 daN | 760 daN | 600 m | 2 | 60/90 |

| MC65 | 19 mm | 625 daN | 1000 daN | 500 m | 2 | 60/90 |

| MC85 | 25 mm | 785 daN | 1260 daN | 500 m | 2 | 60/90 |

| MC86 | 25 mm | 925 daN | 1490 daN | 450 m | 2 | 60/90 |

| MC105 | 32 mm | 1500 daN | 2400 daN | 300 m | 2 | 60/90 |

| MC106 | 32 mm | 1500 daN | 2400 daN | 300 m | 2 | 60/90 |

Applications of Polyester Composite Strapping

6. Agricultural and Timber Industry

- Ideal for bundling harvested crops, firewood, or stacked timber. Its corrosion-free nature and weather resistance make it suitable for outdoor environments.

7. Industrial and Manufacturing Use

- Secures components, machinery parts, and heavy equipment for transport or storage.

1. Palletizing and Bundling

- Secures boxes, cartons, and palletized goods for safe transport and storage.

2. Timber and Wood Products

- Holds logs, planks, and lumber bundles firmly without damaging surfaces.

3. Metal Sheets and Pipes

- Safely straps heavy steel or aluminum sheets, rods, and pipes during shipment.

4. Construction Materials Logistics and Transportation

- Ideal for securing bricks, tiles, cement bags, and other bulky building materials.

5. Export and Logistics Packaging

- Ensures load stability for long-distance, sea, or air shipments.

What We Can Do?

We provide a comprehensive range of OEM and ODM services for Polyester Composite Strapping to support your brand’s packaging requirements. Custom colors, printing options, and tailored specifications can be produced to match your exact needs. Whether you require specific widths, strengths, coatings, or branded markings, our team delivers flexible and reliable manufacturing solutions designed for global procurement standards.

FAQs (Frequently Asked Questions) About Polyester Composite Strapping

Polyester composite strapping is a high-strength cargo securing material made from polyester fibers encased in a durable polymer coating. It provides strong load retention, shock absorption, and a safer, non-metallic alternative to steel strapping.

Common widths range from 13 mm to 25 mm, with linear breaking strengths from 295 daN to 1500 daN, depending on the strap type and manufacturer.

It is lighter, safer to handle (no sharp edges or snap-back), corrosion-free, reusable, and offers better shock absorption. It reduces labor strain, freight damage, and overall packaging costs.

Yes. Polyester composite strapping is fully compatible with standard phosphate-coated or galvanized wire buckles for secure and adjustable tensioning.

Yes. It resists UV, moisture, and moderate weather conditions, maintaining tension and load security even on long multi-modal shipments.

Consider:

Weight of the load

Required linear strength and system strength

Environmental conditions

Type of cargo and packaging

A supplier can assist with selecting the optimal specification.

Yes. Unlike steel, it has no sharp edges or snap-back hazards, significantly reducing the risk of workplace injuries during application or removal.

Industries include:

Timber & lumber

Steel fabrication

Chemical drums & IBCs

Machinery & heavy equipment

Construction materials

Brick & block packaging

Logistics, warehousing, and export containers

Store in a dry, cool environment away from direct sunlight or chemicals. Avoid sharp objects to prevent damage to the strap rolls.

Yes. It has low equipment cost, reduces injury risk, eliminates rust issues, and is easier to handle—often lowering overall load-securement expenses.

Why Us

Quality First

Products tested for tensile strength, elongation, and performance stability.

10 Years of Expertise

Over a decade producing and exporting industrial-grade strapping worldwide.

OEM/ODM Specialists

Custom sizes, strength,printing,labeling, and flexible MOQs to suit your brand’s needs.

System-Based Solutions

We don’t just sell straps — we provide complete load restraint systems.